Aluminium with its high specific strength and castability makes it superior compared to other materials. On comparing with Cast iron, it is 65% lighter enabling for a lower GVW and improved Fuel efficiency in automobiles. Aluminium alloys are 2.5 to 3 times less dense than Cast Iron. This lower density translates into notable weight advantage. The following data table will help you to have a clear insight of the technicalities:

Density: 7130 Kg/m3

Strength-to-weight ratio: ~60,000 Pa.m3/Kg

Density: 2700 Kg/m3

Strength-to-weight ratio: ~99,000 Pa.m3/Kg

Aluminium castings can improve strength and stiffness by increasing material in vital areas, while maintaining an overall lighter weight.

When it comes to Stability particularly in off-Highway and HC Vehicles, cast iron takes a lead but with optimised part design Aluminium castings takes a better position and now it has been proved in the market by many OEM's.

One such example weight reduction and productivity proven by Craftsman Castings is the Transmission Housing for the tractor segment. The intricate part profiles, wall thickness and annual demand drives us to go ahead with High Pressure Die Casting Process. Transmission housing being an intricate part of the powertrain, was made earlier from Cast Iron. Cast Iron was able to give the required strength to the part but was not contributing to the weight and productivity. On close working with OEM's, Craftsman Castings revolutionised this part and successfully converted it from Cast Iron to Aluminium.

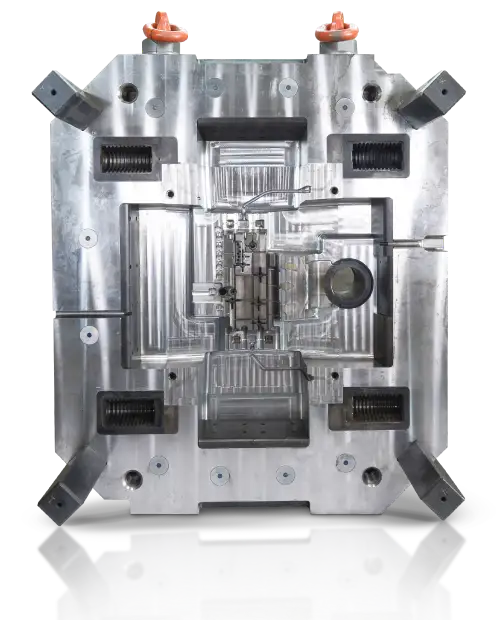

The in-house toolroom has helped us tremendously to curate the die for this part, which has world class manufacturing facilities with mould flow software to deliver the best die solutions for the process. This die is tailored for the HPDC 3200 Ton machine.

The transmission housing is a vital part of vehicle that helps to protect the gears and other key components from dirt, debris, and other elements that could damage or interfere with their performance. The housing holds the transmission oil which provides lubrication and to prevent over-heating. Aluminium with its high thermal conductivity (96 W/m K for ADC12 alloy) compared to 52W/m K of Cast iron helps to dissipate the heat faster. Since the housing carries oil, it has to be leak free. Our in-house Special Purpose Machine division fits like a charm to ensure the leak proof transmission housing.

It designs leak testing machine dedicated for the transmission housing part. These leak testing machines are highly efficient and completely designed and manufactured in-house. This customised leak testing machine will help us to speed up and launch the program on-time, without compromising on the quality

Craftsman Castings being an end to end solution provider, is a master in casting, machining and special purpose machine manufacturing as well. With our best in class machining facilities, we are able to supply fully finished aluminium parts to the assembly lines.

Hence laying the foundations strong and right turns out to be a profit generation activity in long run for the casting industry.

The in-house capabilities of Craftsman Castings along with the bright mindsets present here, enable the successful launch of this conversion taking a lead towards sustainable mobility.

# Think Craftsman; Think In-house

Light weight

Higher Productivity and scalability

Better Heat dissipation

Cost savings

Better Mileage